Working Around the Clock

Any good project manager will tell you that mechanical engineering hardly ever goes exactly according to plan. One of our best and brightest helmed a 2018 project in Denton, Texas that saw the project’s deadline compressed into a shorter-than-normal time frame. Working around such tight parameters was a challenge for our team, but one we were determined to meet.

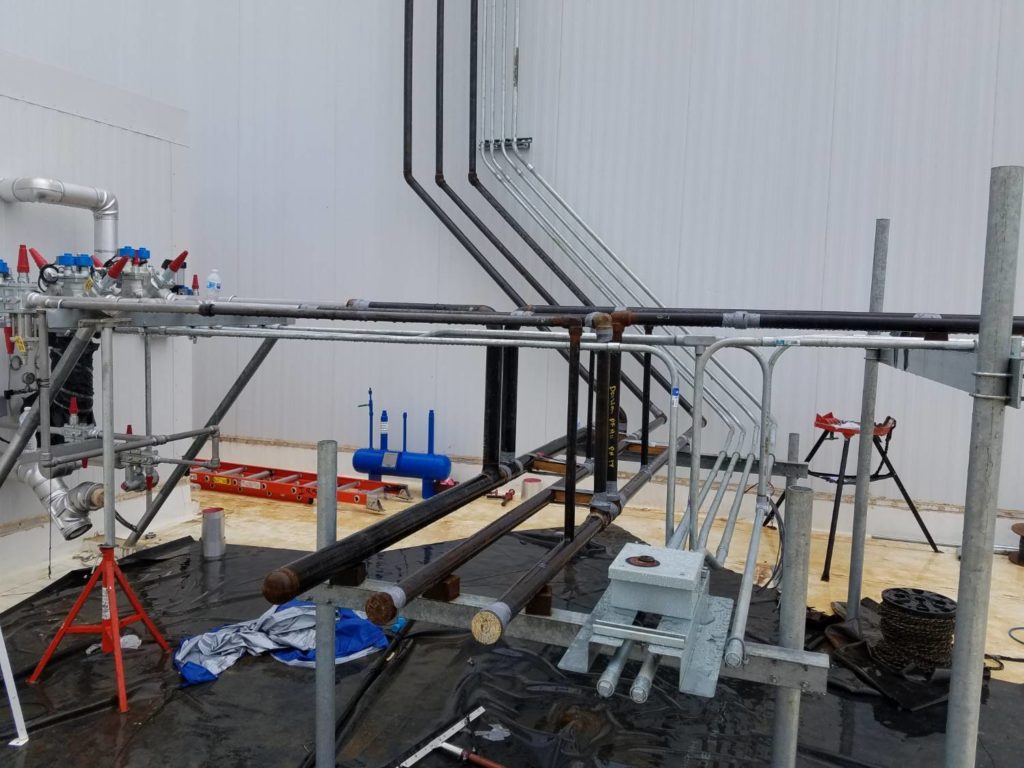

Last summer, our client was ready to break ground on its new Denton facility, and Innovative was awarded the contract. The specs for Denton called for 17 penthouses, plus convertible rooms refrigerated by a low-charge, direct expansion ammonia system.

According to our project manager, this was at least a 20-week project on paper. But the customer asked us to expedite the Denton timetable so that it would be able to move product in on Sept. 1–just a bit under 17 weeks after the initial start date.

The dilemma was clear: how can Innovative meet the needs of the client without compromising safety or quality?

Fortunately, our dedicated work crew was on the case. We were on site on May 1, setting up the underground electrical infrastructure and laying underfloor glycol. We had exactly four months to take a building that didn’t even exist down to the requested temperatures, which were as low as 10 degrees in some of the more specialized areas.

For the duration of the Denton contract, our teams doubled up on shifts and worked around the clock to finish this 5-month project in the requested amount of time.

“With the shortened time frame, this was a heck of a build,” our project manager said.

Our Denton expansion has a happy ending. Our team loaded the ammonia on Aug. 23, and the Denton facility was at temperature on Sept. 1–right on schedule!

Our Denton PM wasn’t shy about praising the manufacturing teams that worked overtime to meet our clients’ needs. “To achieve this took incredible dedication and additional effort from all the staff involved,” he said. “From management down to individual on-site workers, this was an incredible success story for Innovative.”